Design and Construction of Mega Solar =Vital Power=

For solving Japanese energy problems and maintaining healthy status.

For solving Japanese energy problems and maintaining healthy status.

We have many records from solar facility for general house appliances to Mega Solars, and have engaged this business since 2001. In many cases, the installation of power plants is done by people other than electric constructors. But, because we are the professional of electric engineering work, customer can trust our skills for best solar power generation.

| Health Making | Frame installation to farmlands and parking lots, Panel installation of each manufacturer, Installation of inverters (power conditioners), Installation of boosting transformer facilities, Installation of PCS room, Installation of lead-in line pillar. |

|---|

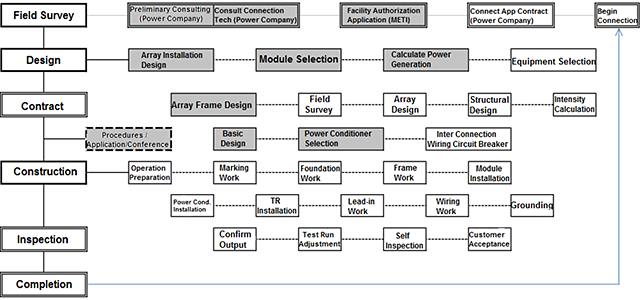

The location of electric power supply is very important when installing solar power generation. It begins from checking of grid-system. And in case of farmlands, the feasibility of farmland conversion (change of land usage purpose) is also an important factor.

| Land Making | Installation to farmlands and forest lands, Installation to parking lots, Installation to golf course sites, Effective installation to factory roofs, Installation to flat roof of buildings, Installation to sloped roof of apartments, Reinforcement frame installation to carports, Installation to general housings |

|---|

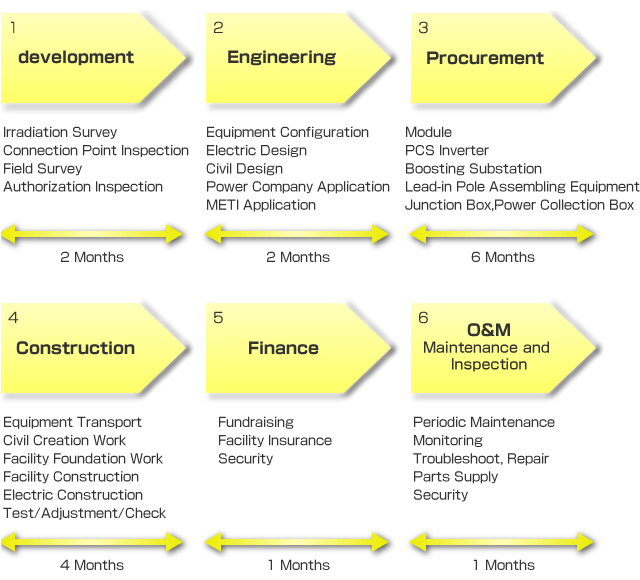

Professional designer will gather field survey results and create effective designs for maximum power generation and for compatibility with substations, extraction of power generation efficiency. Then designer will decide the facility specification such as area the scale of facility. Plant design will be made based on above. And documents for the Ministry of Economy, Trade and Industry (METI), power companies/Agriculture Committee, and etc. is made, then necessary process is taken by them.

| Plan | From Design of panel combination to Design of PCS wiring, Design of high-voltage transformer facility for boosting, Design of arrangement plan, System structure design, System wiring design, Equipment design |

|---|

We heard the story that maintenance of solar power plants is unnecessary, but we believe this is rather unreasonable. If power generating facilities do not generate power efficiently and effectively, the cost will be increased. We recommend you to put sufficient preventive maintenance into effect

| Health Maintenance |

The Maintenance Contents1. Insulation resistance measurement2. Measurement of opening voltage and generated voltage of every array - Check the generating state of circuits and arrays of each panel. (A few panels of performance inability have been found.) 3. Capability testing of inverters (power conditioners) - Protection state and power rate check by linking with Tokyo Electric Power Company (Fixed range from power company - Depending on transmission state) 4. Damage inspection of rectifier in junction boxes - Are there any damage by such as lightning? 5. Panel installation state check - Whether there is electric erosion 6. Confirmation of looseness state of basic frame – Check for bends and twists from strong wind. State check of the base. Are there any water leaks? 7. Module cleaning – Indispensable especially for plant at outdoor, open field. |

|---|

| The contents of equipment check | |

|---|---|

|

PCS (power conditioner, or inverter) "Base unit and sub unit" |

1. No generation insulation test 2. Generation initiation charging test 3. Active synchronization test 4. Protection relay test (OVR/UVR/OFR/UFR/OVGR etc.) 5. Insulation test, Grounding measurement 6. Cooling unit test and state inspection 7. Surrounding environment temperature test |

| Others | Exterior check, dirt, scratches, allophone, stench, overheat, ventilation filter, indicator check |

Copyright © 2014-2026 Japan Electric Power Service All Rights Reserved.