The Power of Japan Electric Power

Service is The Human Power of Staff.

The elements which compose the human power are the power of

"Skill", "Cost", and "Added Value".

We nurture staff members that can create a synergistic effect

with these three elements, and to respond the customers’ needs.

| Technological Training | Our staffs acquire technical knowledge and the latest technology. And we hold a basic knowledge seminar once a week every year from April to September. (Periodic Sessions) |

|---|---|

| Practical Training | We hold practical training concerning protection relay tests and the structure of a breaker (from dismantling to construction) at our training room under the guidance of a professional engineer. (Specialized field workshop) |

| Technological Assessment | Technical staffs are ranked based on their skill by “Engineer/Assistant Engineer/Technical Assistant/Assistant Member” by using in-house ranking system. (Skill level classification criteria) |

| Safety Education | KYT Risk Prediction Training Education, Foreman Education, Quality Control Education |

| Value Education | Profession Education, Manner Education and Positive Thinking Education |

Technological Study Session

Once a month from April to September, we hold a study session,

where the senior staff play as the lecturer,

in order to improve the skill and quality of construction techniques and inspection methods.

We are a group that aims for acquisition of higher level technology and to be “Electric Doctors”.

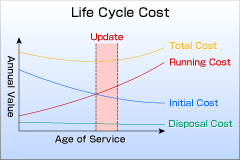

For certain period after construction, the magnitude of initial cost during construction is significant. However, over time, the running cost increases. It is very important to propose how to lower this running cost.

-How to Reduce the Running Cost-

1. Choose a maintenance company with high reliability and high skilllevel.

2. Choose a reliable and low-cost repairing company.

3. Choose a company that can do integrated work from inspection to

repairing / modification.

4. Update / Renew when the total cost becomes lowest.

5. Periodically perform maintenance (more than once a year).

Result Presentation

Every year on July 1st, all the employees including the new faces present the results of the projects they took charge of. This develops the skill of cost management from the customers’ view.

Moreover, appealing individual contribution by their effort leads to experience the participation in management.

・We productize the reliability and low-cost by in-sourced construction.

・We contribute by integrating environmental maintenance and environmental conservation into our business.

・We have integrated technology from inspection to construction with cost consideration.

・We have established a total system of Planning → Design → Construction → Inspection → Maintenance → Testing → Repair/Renew.

・We continue providing comfortable tranquility on a round-the-clock basis.

・Our staffs are hard working.

Educational Training

We perform a Safety and Health Committee Activity every month based on the Safety and Health Regulations,

and hold a comprehensive Safety and Health Convention twice a year.

We are seeking to be the safest company in Japan.

Study Session

We improve our sensitivity and awareness, and absorb each other’s way of thinking with flexible ideas

by using a management magazine called “Principle and Management” as base material, once a month.

We value exchanging opinions in discussion form to broaden our minds.

And we perform sessions for "customer satisfaction".