Electric Check and Maintenance=Health Check=

To prevent even the slightest chance of accidents, we do inspections of the heart of the building (incoming and transforming facilities) on a regular basis.

To prevent even the slightest chance of accidents, we do inspections of the heart of the building (incoming and transforming facilities) on a regular basis.

Once a year, we stop all electricity in the building to do an inspection.

Protection devices for high-voltage transformers,

cut-off gears and substations are periodically inspected and tested in detail.

| Places to Check | Present Extra High-voltage Facilities(66000V, 22000V), Duplicate Power Incoming Facilities, Loop Transformation Facilities, Spot Network Facilities, Regular High-voltage Substation Facilities, Low Voltage Load Facilities, Home-use Power Generation Facilities (High/Low Voltage), Storage Battery Power Income Facilities, CVCF Facilities |

|---|

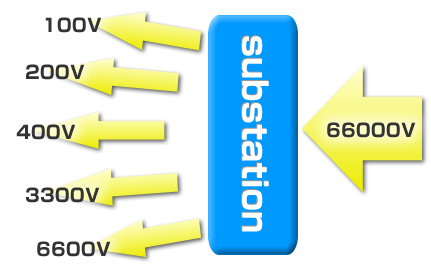

Electricity for buildings and factories is sent from the electric power company with high voltage.

Therefore, we need a facility to lower the voltage.

This facility is called a substation. It is the heart of the building and is a very important facility.

We perform a completion check upon the completion of a facility construction,

because buildings and electric facilities are composed of multiple delicate instruments.

After completion, we perform a minute diagnosis to prolong facility life

and to maintain equipments to normal state.

| Diagnosis Item |

■Completion Check Completion check when installing high-voltage cubicles (voltage resistance test / measurement) Structure examination (partial damage check, control indication check, main circuit check) ■Minute Diagnosis Insulating oil analysis, VCB minute test, and other performance checks. |

|---|

A completion check is an examination after the completion of the substation construction

and before handing it to the client to make sure the electric facilities were constructed

in accordance with the blueprint and law and possess the necessary abilities.

It is a diagnosis to maintain in detail the performance status each equipment possesses in addition to the yearly periodic inspection. Figuratively speaking, it is like a medical check-up for humans.

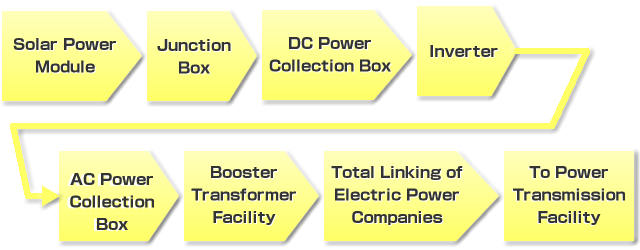

Solar power generating facilities installed outdoors is exposed to the weather.

Therefore, they are vulnerable to heat, humidity and dust,

which leads to the decline of electric generating ability and operation trouble of cut-off devices.

Periodic maintenance is necessary to always maintain the equipment in a normal state,

and demonstrate 100% of its ability.

| Diagnosis Item | Maintenance of Solar panel and wiring, check of frame fixation condition, junction box, assembly box, pyrheliometer, temperature meter, data gathering device, inverter (power conditioner), ground resistance measurement, insulation state measurement, battery measurement, generated energy measurement, open circuit voltage measurement, appearance maintenance, grid interconnection protection instrument performance test |

|---|

Electricity hates moisture absorption and dust.

We clean every small part of the equipment, not only to launder,

but also to improve the performance (insulation ability=voltage endurance)

it originally possesses, and prevent the Tracking phenomenon.

| Diagnosis Item | High-voltage cubicle facility, open transformation facility, and low voltage panel board Monitoring control board, electric furnace electrolysis facility Cleaning of equipment’s insulation restoration part, live-line cleaning of low voltage board, detailed cleaning of transformation instrument |

|---|

Dust gathers between the outlet and plug. This dust adsorbs humidity and causes

repeating spark discharge between two poles.

When insulation state deteriorates, electricity flows through both plug extremes,

then there is heat and ignite, which is called as “Tracking Phenomenon”.

Transformation facilities are of high-voltage and therefore more likely to engender the phenomenon,

leading to short circuit and ground fault.

Copyright © 2014-2025 Japan Electric Power Service All Rights Reserved.